| Jeep TB Conversion for 2gnt

Eclipse/Talon

By MetalJim

The stock 2gnt TB is

52mm. The throttle bodies for 90�s Jeep

4.0L I6 are 55-60mm.More air means

more fuel means more POWAH!!!The good

news is that the Jeep TB can be modified to fit on our cars.

The donor TB in this write-up is for a 91-95 Jeep Wrangler,

Cherokee, or Grand Cherokee, but any TB from a 91-99 will work. I bought it used for $60 on eBay. If the donor is used then this mod is relatively

cheap � compared to having the stocker bored, or buying a bored TB, or buying a

billet TB. It is, and will most likely

remain, the cheapest way to get more air.

A new one will work but the costs are higher. Also, there are several outfits that offer 62mm bored Jeep

TBs. Here is a link with some good

aftermarket Jeep TB info:

http://www.jeep4.0performance.4mg.com/

If you need some serious air then here are a couple of links

for Jeep TB specialists:

http://www.accuratepower.com/

http://www.turbocity.com/

I want to explain the 55-60mm range. The inlets(filter side) on all of these Jeep

TBs are 60mm, but some of them taper to 55mm on the outlet(manifold side). I don�t know for sure, but it may have

something to do with what year the TB is for and/or weather or not it was made

for an automatic or manual transmission.

If all you want is 55mm then hey that�s great�but fear not! If you want 60mm then you shall have

60mm. I found a great write-up on

removing the taper, and it turns out that the taper is easily removed �

creating a nice 60mm bore through the entire TB. Mine started out with a 55mm taper, but now its gone. Nothing left but a beautiful gaping 60mm TB

all the way through. Of course if you

can manage to find a true 60mm Jeep TB then you won�t have to bother with the

taper. Anyway - here�s the taper

removal link:

http://go.jeep-xj.info/HowtoTBboring.htm.

There are some clearance issues. The Neuspeed bar � is a no-go with this TB.

It simply will not fit with a Jeep TB.

Also, there is approximately .4 inches

clearance to the hood after it is installed.

The IAC housing is the highest point.

The good news for those with � inch phenolic intake manifold spacers is

that the TB juts toward a strength channel, which could easily be modified to

allow a Jeep TB to fit.

One more thing before we get started. You�ll notice that the 2 TBs are kind of

backwards from each other. The IAC is

on the bottom of the 2gnt TB, but the Jeep one is on top. The throttle plates actuate in different

directions � clockwise vs. counterclockwise. The 2gnt TB has 2 very deep

mounting holes diagonally opposed, while the Jeep TB has a puny little 4-bolt

base. Don�t worry - really, it�s ok.

Ok, enough about size, cost, options, tapers, caveats and

funkiness - lets DO IT!

Remove all of the sensors as well as the butterfly plate,

throttle shaft, and spring from both TBs.

All of these bolts are Torx T20.

The bolts on the 2gnt butterfly plate may shear when you take them out �

the damn things are dimpled on the end.

Take your time and work them back and forth, like you would when tapping

a hole.

You�re going to use the 2gnt throttle shaft on our

Frankenstein TB, so if the bolts do shear out � remove the remnants with an

extractor.

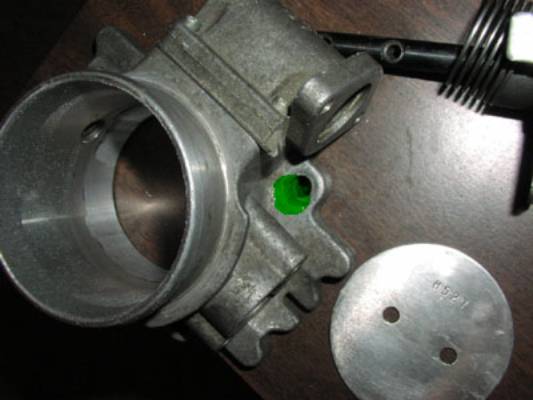

Like I said, you need to use the

2gnt throttle shaft. However the slot

needs to be widened to fit the Jeep butterfly (green slot lines � upper

picture). I used a die grinder, but you

could use a Dremel with a cutting wheel as well. The slot only needs to be widened enough to fit the new plate. I

noticed a nice natural size marker on the 2gnt shaft � the bearing race

marks. If you make the slot as wide as

the bearing marks (green arrows � lower picture) the plate should slide right in.

�so that it looks like this.

You need to cut the spring seat

(marked in green) so that our 2gnt shaft will fit far enough to install the

butterfly into the Jeep TB. The seat is

made out of a hard plastic and cuts easily with a utility knife if you just

whittle thin chunks. That�s right, I

whittled it. I just thought that would

be the most precise way to do it. It

actually didn�t take that long. A good

reference mark to cut to is where the spring seat tapers to the shaft(line

marked in red). So long as you cut

enough away that the butterfly can be installed � that�s the real point. I kept checking my work as I got closer by

inserting the shaft and placing the butterfly over top of it.

�till I could see through.

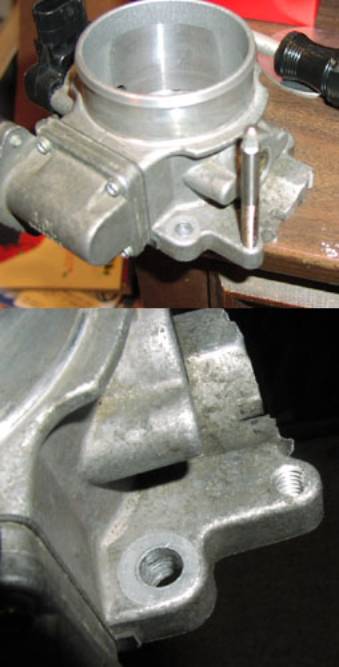

The base plate on the Jeep TB

needs to be cut away so that our 2gnt throttle shaft can rotate freely to WOT

(wide open throttle). Remove the

idle-set screw from the Jeep TB cause it�s in the path of destruction. The section marked in red needs to be cut

away. It is important to note here that

you MUST keep the slot in marked in green.

Don�t cut that slot out of the picture because we�ll need to secure the

spring in there. It�s also important to

note here that you MUST keep the last nub outlined in yellow. This is where we need to install the

idle-set screw. The safest way to go on

this one is by the eyeball and testing along the way. Cut enough away so that you can slide the butterfly plate into

place. Make sure you have free and

clear travel to WOT on the throttle shaft with the butterfly installed.

It should look something like this

when you�re almost done.

Our new TB is going to use one

Jeep spring. The stock Jeep spring is

actually 2 springs banded together.

Remove the band and separate them, cause we only need one.

In the next step we�ll be

modifying the 2gnt shaft to fit the Jeep spring. The modification looks a bit hokey at first, so I�m going to

explain the reasoning before we jump into it.

I actually had a lot of problems with getting enough spring

tension. The 2gnt TB comes with 2

springs, like the Jeep. The 2 springs

together were too thick to fit, so my first spring attempt was 1 of the 2gnt

springs, but it was too weak. It

wouldn�t return to idle after it was installed. So I looked to the Jeep spring.

It worked fine at first when I was just kind of cruising around. But the first time I really mashed on it all

of the sudden it wouldn�t return to idle easily. Turns out that the whole spring wasn�t effective � only part of

it because its smaller in diameter than the 2gnt spring and it was binding up

on the 2gnt spring seat. Look at the

springs/spring seats side by side. The

Jeep spring is thicker and smaller in diameter. You could also just go buy a bunch of springs until you find a

setup that works. Personally, I felt

compelled to source as many parts from the stock and donor TB. My conundrum was 2 springs don�t fit and one

2gnt spring is way too weak I was left with 2 choices � use the jeep spring

seat on the 2gnt shaft, or modify the 2gnt spring seat so that the Jeep spring

fit loosely on it. I chose to modify

the 2gnt spring seat. You can probably

cut the 2gnt spring seat down to the point where you can install one half of

the Jeep spring seat on the 2gnt shaft�but I chose to modify the 2gnt spring

seat � and it works great. So there you

have it.

So, we need to cut the spring seat

down so that the Jeep spring fits loosely on it. You�ll have to cut off the entire outer circle of plastic and then

just a little bit of the radius beams.

Again, it�s this hard plastic that can be cut pretty easily with a

utility knife. At this point it will

become blindingly obvious that the Jeep spring is backwards. What I mean is that instead of the spring getting

smaller when the throttle actuates, it gets bigger. I�ve been running this setup for a few of weeks now with no

spring tension problems. You�ll be done

when you can easily slide the spring onto the newly cut seat.

At this point, it should start

looking more like an actual TB. Please

disregard the fact that I�m using the 2gnt spring in these pictures. Like I said � I had spring problems.

Remove the 55mm taper if you want

to. I did it with a rotary file on a

drill press. Big ol� whoppin 60mm TB all the way through. Ahhhhh.

Follow the link at the top of this write-up for more detailed

instructions on how to do it.

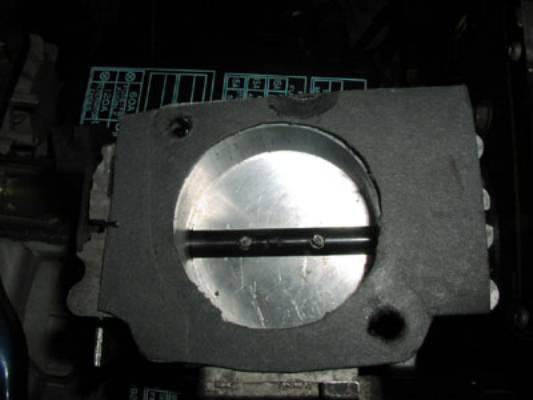

Moving right along. The bolts on the 2gnt TB are way to long to

work on our puny little Jeep base.

You�re going to need to buy M8x25 1.25 pitch Allen head bolts for

mounting the new Jeep TB to our intake manifold. It�s very important that you get Allen head bolts because after

you make the new mounting holes in the Jeep TB, there will be NO room for a

regular hex head. The mounting holes on

the 2gnt TB are just about 3.3 inches apart center to center. That falls just inside the edge on the Jeep

holes. You need to drill new holes that

are essentially centered over that imaginary 3.3-inch mark inside the edge on

the Jeep holes. I used a 21/64th

inch bit in a drill press. It worked

ok, but I did have to ream the holes a bit to get the bolts to actually screw

into the manifold. When you�re

fitting/reaming the TB to the manifold, make sure you ream equally on both

holes. There really is not a lot of

room from the edge of the hole to the housing by the time it fits.

You can use the 2gnt Throttle Position Sensor just like it is.

The Idle Air Control motors look pretty

much identical, but the tips are different.

You have to use the 2gnt IAC motor with the tip from the Jeep. The tips screw out. They�re in real tight, but they will

unscrew. Take note of the tip height on

the 2gnt sensor before taking it off.

When you install the Jeep tip on the 2gnt IAC, set it to the same tip

height. I did, and it seemed to work

very well (it idled properly the first time I fired it up).

One of the great benefits of using

an OEM throttle body is the beautiful fitment of the butterfly plate within the

bore. You�ll notice that when the

throttle plate is shut, even if it is shut lightly, the plate will stick into

the bore of the TB. It�s a perfect

fit. When you crack it open feel that

it�s stuck and you can hear it click getting unstuck. The fitment is nice, but the sticking has to go. That�s why the stockers have idle-set

screws. Their purpose is to NOT allow

the plate to stick in the bore when it closes. They need to be set to stop throttle shaft rotation just before the

plate sticks. The reason is that, if

you let the plate stick � off idle throttle response feels jumpy. It turns out that a �-20 hex head bolt fits

the job perfectly.

Use a 13/64th drill bit

to drill a hole in the nub we saved from our initial base plate work (the nub

that was outlined in yellow). It needs

to be pretty close to the outside edge. Leave enough material to support a threaded bolt. Then tap the hole with a �-20 tap. Run a nut on to your �-20 bolt � we need it

to lock the idle-set screw. Then

install the idle-set screw. Set it to

where the butterfly no longer sticks into the bore of the TB and lock it in place

with the lock nut.

One fairly drastic difference

between the 2 throttle bodies are the idle air channel. The 2gnt TB uses a secondary port on the

manifold where the Jeep uses a plate bypass. You need to plug the idle port on the manifold or else you�ll get mad

vacuum leak and idle at 4000 RPM. The

idle port on my 95 Eclipse RS manifold is a � inch big. I�m not sure if all of the holes are the

same size on all of the years of 2gnt so please measure yours before buying a

plug. Since mine was � an inch, I got a

� inch button plug. Spread silicone on

the lip of the plug and plug the hole. Shove it in there firmly and wipe off the excess silicone so it doesn�t

get onto the gasket material when you install the TB.

Which brings me to the

gasket. I used 1/16th inch

thick gasket material to make the gasket.

It needs to be at least that thick because of the plug. The head on the button plug I used is not

exactly thin. I needed to use a thick

gasket material in order to get a good seal to the manifold. You can see the dimple made by the button

plug in this picture.

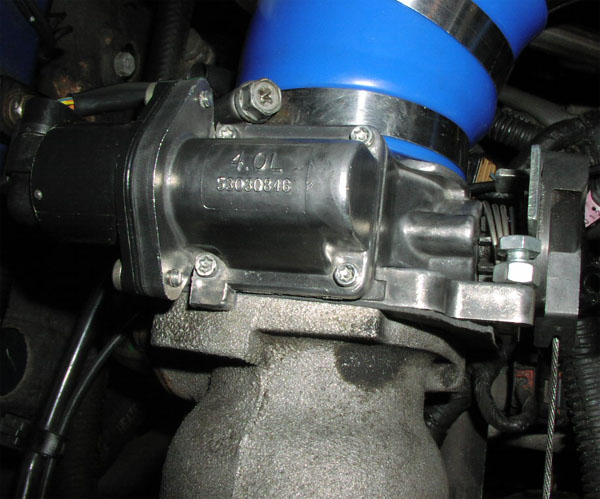

>We�re almost done. Take the assembled TB - latch it onto the

throttle cable and bolt it up to the manifold with the gasket in place. Hook up the sensors. I know you want to fire it up but first

you�ll need to adjust the throttle cable.

The shaft on the Jeep TB is a little further away from the intake

manifold than the 2gnt stocker, so you�ll most likely need to adjust the cable

a little. What you want to do is make

sure that the throttle shaft clicks nicely onto the idle-set screw just like it

would if you were holding the TB in your hand.

Even when you test it for very small openings, like with a nudge, it

should still click when it shuts. If it

doesn�t click then the throttle cable is still to tight, loosen it up.

Ok now, LET IT RIP! What else can I say here? It should work like a charm. If it doesn�t, then you messed something up

� check your work.

Other than that - You could ream the intake manifold out to match the new bore capability. I haven�t done that yet. The manifold inlet is somewhere around 55-57mm stock. I�m sure I�ll get around

to match it up to my new TB at some point, probably sooner than later. I�m N/A right now. I do have other air flow mods � cheapo eBay short ram intake,

drag cams, ported exhaust manifold, test pipe, and a GS-T exhaust. The power I got from upgrading to the Jeep

TB definitely noticeable. I won�t get

into the numbers because everyone�s setup is different, but I will say that I

couldn�t be happier with the results.

Inarguably, for our cars, a TB

upgrade is a good thing. 52mm just doesn�t quite cut it. How much bigger

is up for debate. 55mm may be good for

you. If it is don�t touch the

taper. Maybe you want 57 or 60mm? Well

then go nuts with the taper. You may

want a 62mm bore job for a racecar. It�s

doubtful at this point that a 68mm TB would be considered as anything other

than overkill but there are aftermarket billet Jeep TBs of that size � and they

could be fit to your 2gnt. Who knows �

If Gary ever builds that aluminum race block, someone may actually NEED a 68mm

TB.How much bigger is up to you and

your setup.

I purchased a spare 2gnt TB to do

this mod, but I can sell mine now that I don�t need it anymore. I wanted to make sure that the mod would

work and was worthwhile before tearing my original TB to shreds. Really the only things I HAD to buy were the

Jeep TB, 2 M8x25 1.25 pitch Allen head bolts, a � inch button plug and the

gasket material�. because it does work, it is worthwile, and I already had all

of the tools to do it.

Oh I have to mention this - even a used one looks pretty tight after a bit of polishing with the Dremel.

Note: The part number for the 1991-1995 Jeep Grand Cherokee 4.0L Throttle body is 53030844.

The picture shows 53030846 which is the IAC housing and may be confusing if you are shopping for a throttle body.

|

|

Document statistics:

Last modified on 2009-02-06 17:52:34

by noboost

|

|