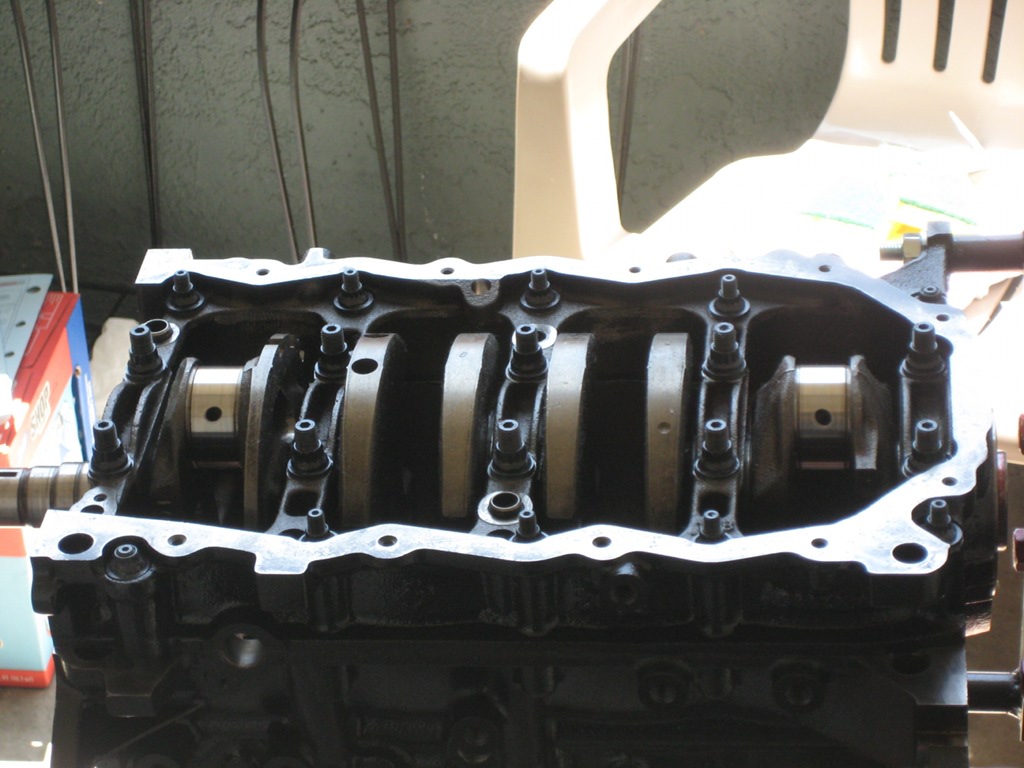

| Strangely, ARP does not have a kit for the 2.4L EDZ main studs. It must be purchased a la carte. The 2.4L motor shares the M8 and M11 bolts as the 2.0 however they are 10mm longer. If you search deep enough you will find some neon enthusiasts will run the 141-5801 kit for the 2.0 however back the stud out a couple threads to provide the nuts enough engagement criteria. This defeats the purpose! OEM: 2.0 bedplate bolts: M8 x 1.25 x 60 M11 x 1.50 x 65 OEM: 2.4 bedplate bolts: M8 x 1.25 x 70 M11 x 1.50 x 75 After a couple phone conversations with Paul @ARP (very helpful guy) I ordered a set of studs/washers/nuts a la carte. QTY 10: M8 stud: AF3.725-1BQTY 1: 5/16" ID | 13/16" OD washer kit (no Chamfer): 200-8588QTY 10: M8 nut: 300-8340QTY 10: M11 stud: ATP4.000-1LBQTY 10: M11 washer: 200-8510QTY 10: M11 nut: 300-8303*part numbers above link to product pages at Summit Racing* This package is not plug & play! The M8 holes in the block have approximately 2mm of unthreaded material. For the M8 studs to work properly you must use an M8x1.25 bottoming tap in order for the studs to thread fully. Without this the nut will run out of thread above the bedplate and you will not have an accurate torque reading.Due to casting flaws/differences the 5/16" ID | 13/16" OD washer is a very tight fit. There are washers available with a smaller OD if you want however I did not have to machine my bedplate for these washers to work. I did however need to use the hex head to loosen the stud slightly so that it could move a bit so the washer could seat completely. Snug the stud down once again.As with all ARP hardware ensure you coat both sides of the washer, flat surface of the nut, and threads with their moly lube for accurate torque readings. M11 Nuts: Torque in three steps up to 70 lbs/ft M8 Nuts: Torque in three steps up to 20 lbs/ft Refer to your service manual for tightening sequence.     Wiki by CODE4 Power / Modifications |

| Document statistics: Last modified on 2012-02-25 22:23:14 by DirtMegirt |